What is coffee roasting?

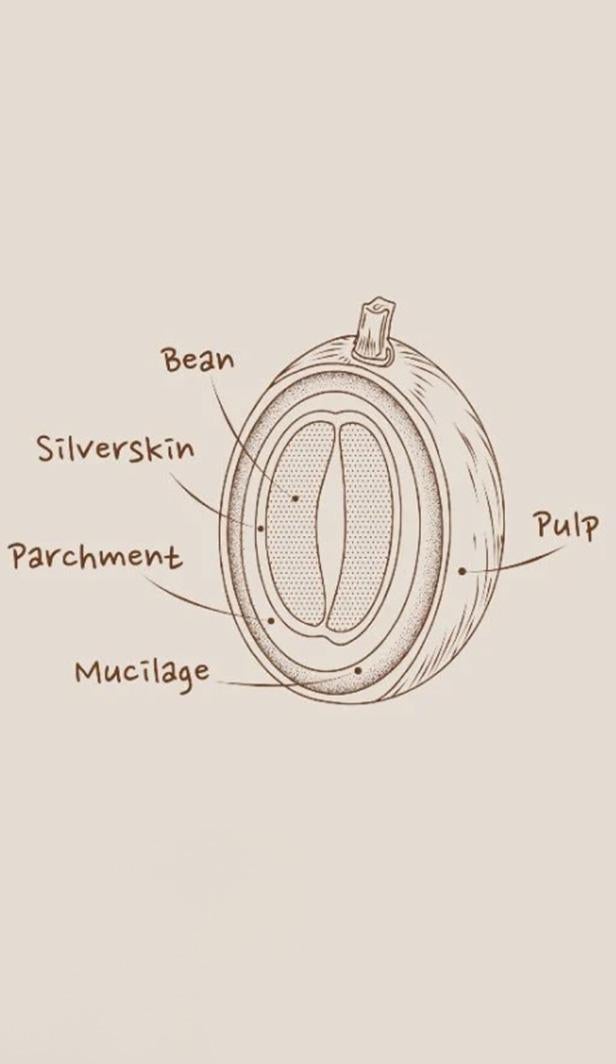

It may surprise you, but coffee beans aren’t beans at all. Rather, they’re seeds which are found inside a fruit called the coffee cherry. After picking the fruit from a coffee plant, the skin and pulp are removed and what is left are the seeds or coffee ‘beans’.

Coffee roasting is the process which transforms these little beans into the coffee you know and love. Different roast profiles and aroma compounds are developed during this process and as such, the temperature and time it takes has a huge impact on the flavour as well as on the colour of the beans.

It’s during the coffee roasting process that different roast profiles and flavours are developed and as such, the temperature and time it takes has a huge impact on these flavours as well as the colour of the beans.

The coffee roasting process in 4 steps

The entire coffee roasting process involves four carefully calculated stages which require a master roaster to ensure each step is completed accurately and that the beans are heated evenly.

1. Drying stage

2. Browning stage

From here the coffee beans will begin to smell a bit like hay or toast, losing their original green colour and grassy aroma – this is a sign that the aroma precursors are changing to aroma compounds. It’s during the browning stage that an exciting process known as ‘the Maillard reaction’ happens. This is where the beans have absorbed enough heat which causes the amino acids and sugars to react with one another as the beans turn darker in colour, creating the unique and distinctive aroma profile for each bean.

3. Development stage

4. Cooling stage

What are the different methods for roasting coffee?

Across all our roasting methods, the energy source for roasting coffee beans is hot air. These are the three main coffee roasting methods we use

1. Drum roaster

This is carried out by classic drum or centrifugal roasters which work by passing heat from the walls of the roaster to the beans by direct contact or conduction. Typically, the beans will be kept moving by a rotating drum to help ensure an even roast. Hot air will also be used with these roasters for a more balanced result; however, this process is known as roasting by convection.

2. Paddle roaster

Hot air coffee roasting is done with a tangential roaster. This form of roasting is often favoured by roasters across the industry as it uses a mechanical paddle and hot air to keep the beans constantly moving. Keeping the beans moving helps to prevent burning as there’s less chance of the beans burning on the walls of the roasters. After, cooled water is usually added as the heat given off by the beans can cause them to continue roasting even after the process has ended.

3. Fluid bed roaster

Likened to the action you see in hot-air popcorn poppers, fluid bed roasting involves the beans rolling over in superheated air that passes upward fast enough for them to behave like a fluid. As all the beans are immersed in the stream of heat, the roast is typically very even, consistent and easy to reproduce. Another great aspect to this method is that unwanted by-products such as burnt chaff, undersized or broken beans get expelled by the hot air draft, allowing for a clean roast. Additionally, some fluid bed roasters feature forced air cooling outside the roast drum, providing the beans with almost instant cooling to prevent the beans cooking further.

Learn more about NESCAFÉ GOLD BLEND Roastery coffee and roasting

Our growers pick only the best beans for your brew and these get put through a careful coffee roasting process to ensure each sip of NESCAFÉ is as memorable as the last. Read our article Inside The Roastery to discover how our coffee is crafted by master roasters behind the scenes.